Fundamentals of prismatic batteries

What is prismatic batteries?

Anyone familiar with the production of lithium batteries knows that lithium batteries can be divided into cylindrical lithium batteries and prismatic lithium batteries according to their shapes. Most of our lithium ion batteries is a cylindrical battery correspondingly. And our large capacity lithium iron battery is a prismatic battery.

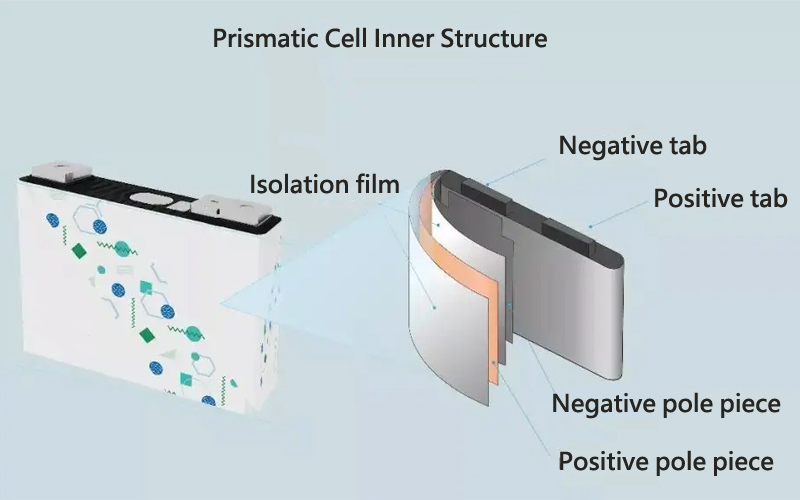

Prismatic lithium battery is a lithium ion battery with prismatic shape, so called prismatic lithium-ion battery. The shell of prismatic battery are mostly made of aluminum alloy, stainless steel and other materials, and the internal use of winding or lamination process.The protection of the battery is better than that of aluminum-plastic film battery (ie soft-pack battery). The safety of the battery Relatively cylindrical batteries have also been greatly improved.

The lithium battery aluminum case is developed on the basis of the steel case. Compared with the steel case, the light weight and safety and the performance advantages derived from it make the aluminum case the mainstream of the lithium battery case eventually. The lithium battery aluminum shell is still developing in the direction of high hardness and light weight technology, which will provide the market with more technologically superior lithium battery products.

Related article《Cylindrical Battery vs Prismatic Battery, What is the difference?》

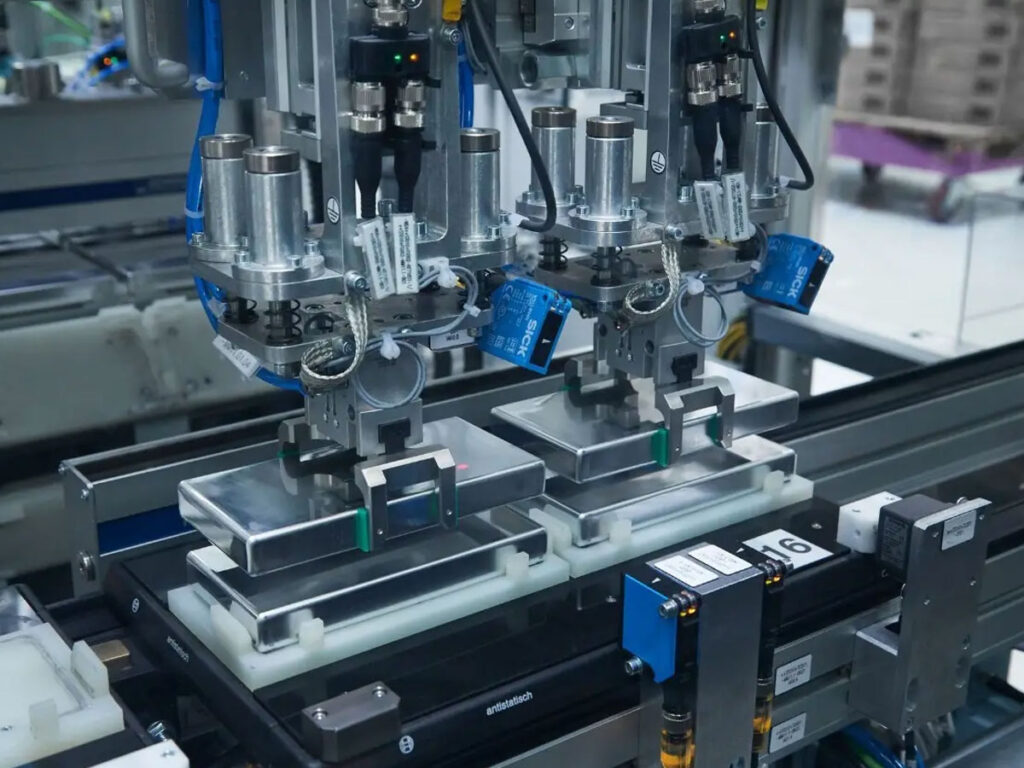

Production process of prismatic batteries

Nearly all the production process are same except the Back-end process. The typical difference is that the prismatic battery cells are uses the Lamination process, while the cylindrical battery uses the winding process. For details production process, you can check our another article 《What is the production procell of lithium battery cells》

Also there are video to show the production process of cylindrical cells in our fatory.

Advantages of prismatic batteries

Compared to cylindrical cells, prismatic cells are significantly more efficient and can provide more power in a smaller package. In addition, the internal resistance of prismatic batteries is much smaller, making them ideal for high-power applications such as electric vehicles and large-scale energy storage systems.

Top 3 prismatic battery companies

There are many companies producing square batteries on the market undoubtedly, among which the most powerful prismatic battery companies are CATL, BYD, and ELB.

CATL

CATL was once the leader in the global new energy vehicle battery industry! Founded in 2011, CATL is one of the first domestic prismatic battery companies with international competitiveness. It focuses on the research and development, production and sales of new energy vehicle power battery systems and energy storage systems. The global new energy application provides first-class solutions. The core technologies include the R&D and manufacturing capabilities of the entire industry chain in the field of power and energy storage batteries. Also materials, cells, battery systems, and battery recycling and secondary utilization.

In November 2019, CATL signed a global framework cooperation agreement with TÜV Rheinland. The two parties will carry out all-round cooperation in areas such as batteries, energy storage systems, related production equipment and production processes.

On February 3, 2020, CATL announced that the company intends to sign an agreement with Tesla, Inc. and Tesla (Shanghai) Co., Ltd. to supply lithium-ion power battery products to Tesla.

The company develops and produces lithium-ion batteries for electric vehicles and energy storage systems, electric vehicle battery modules. Electric vehicle battery systems, powertrains, large-scale grid energy storage systems, smart grid energy storage systems, distributed home energy storage systems, and batteries Management System (BMS). In the field of electric vehicles, the company has established in-depth cooperative relations with top international automobile manufacturers such as Germany and the United States, as well as many well-known domestic automobile manufacturers. To develop and produce power battery systems for pure electric vehicles and hybrid vehicles for global customers. In the field of energy storage, the company has undertaken large-scale energy storage projects for some key customers, and the total annual project volume has exceeded 40 MWh.

BYD

As the world’s leading manufacturer of secondary rechargeable batteries. BYD’s IT and electronic components industry has covered all core components and assembly businesses of mobile phones. Nickel batteries, lithium batteries for mobile phones, and mobile phone buttons have reached the first place in the global market share.

It is worth mentioning that BYD’s blade battery has always been a key research and development project of BYD Auto. Due to the continuous increase in the number of new energy vehicles, battery safety has always been criticized, and the risk of traffic safety accidents has also increased accordingly. Accidents caused by deflagration have become the biggest pain point. In response to this problem, the blade battery is one of the important products to ensure the sustainable development of the battery industry. It has the characteristics of safety, high strength, long battery life, long life and high power. Through the laboratory, the staff put the ternary lithium battery and the blade battery into the laboratory operation room at the same time. Under the same environment, the ternary lithium battery did not last for a few seconds before deflagration occurred.

In the field of batteries, BYD has 26 years of R&D experience and 100% independent R&D and design capabilities. The blade battery factory production line, equipment and other key components are completely independently developed and manufactured by BYD. BYD has always mastered the core and key technologies of battery production. Even global mainstream car brands have begun to use blade batteries one after another. And they are negotiating cooperation with BYD batteries.

ELB

ELB Energy Group is a high and new tech enterprise specialized in manufacturing customized lithium batteries for all kinds of application. Established in 2010,mainly engaged in the R & D, manufacturing and sales of lithium Batteries. Including Battery cells, customized battery Packs, Lead acid replacement batteries, battery modules, Energy storage solutions etc.

ELB have strong tecghnical force, well-trained staff particularly, as well as the professional plant and production equipment. which can guarantee the safety, consistency and reliable performance of battery cells.

Safety, quality, integrity, responsibility are the basic principles of our operation. Reducing environmental pollution and building a clean, green and sustainable development power ecological chain is our constant pursuit.

Products in strict accordance with international standards for production, and obtained the ISO9001, ISO18001, CE,CB, RoHS, BIS,UL,KC, UN38.3 certificates etc.

Strong engineering team, which focus the research and development of lithium battery with more than 10 years experience. Flexible customizd size and capacity according to different project requirements generally.

All product are passed by muti-verification. Qualified product get certification such as CE, UL, MSDS, UN38.3, KC, BIS,CB, etc. Factory get ISO18001, ISO9001 certification.

About ELB prismatic batteries

Model of ELB prismatic batteries

ELB successfully developed 5 prismatic lithium batteries – ELB PC-50, ELB PC-100, ELB PC-120, ELB PC-200, ELB PC-280. For more details, you can visit our resource center to get brochure or spec.

Unique features of ELB prismatic batteries

- Super safe lithium iron phosphate (LiFePO4) chemistry. Which can reducing the risk of explosion or combustion due to high impact, over-charging or short circuit situation.

- Battery Management System (BMS) controls the parameters of the battery to provide optimum safety by protecting against over-charging and over-discharging.

- BMS enhanced design balances the battery cells, optimizing battery performance.

- Delivers twice the power of lead acid batteries, even at high discharge rates, while maintaining high energy capacity.

- Faster charging and lower self-discharge.

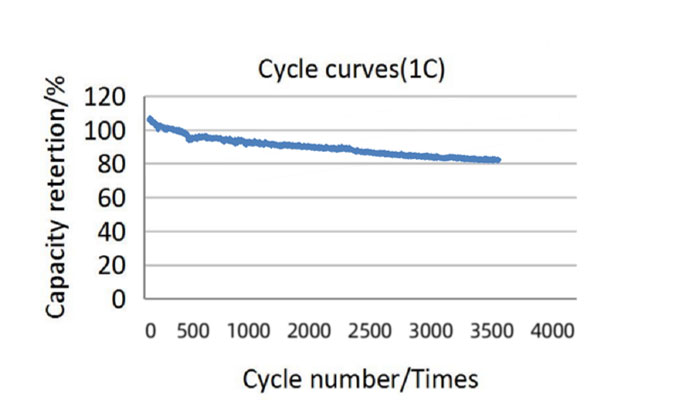

- Up to 10 times more cycles than lead acid batteries.

- Compact and only 40% of the weight of comparable lead acid batteries