BLOG

What is the production process of the lithium battery cells?

What is the production process of the lithium battery cells , how to produce the lithium battery cells? Here we’d take you to visit the factory.

1.Mixing

It can also be called mixing, homogenization, pulping, batching, etc. Through certain feeding sequence, stirring process, vacuum control, temperature control and other conditions, the key components such as positive and negative active substances, conductive agents, adhesives and solvents are prepared into non-Newtonian fluids with certain viscosity and particle size requirements. The viscosity and fluidity of the coating material meet the requirements.

2.Coating

Some companies call it coating. Coating is the process of evenly coating the stirred slurry on the collector and drying it to make pole pieces. Coating methods include continuous coating and intermittent coating. The slurry coating methods of lithium ion battery mainly include scraper direct coating, scraper roller coating and slit extrusion coating. The control parameters of coating products are area density, adhesion, moisture content and so on.

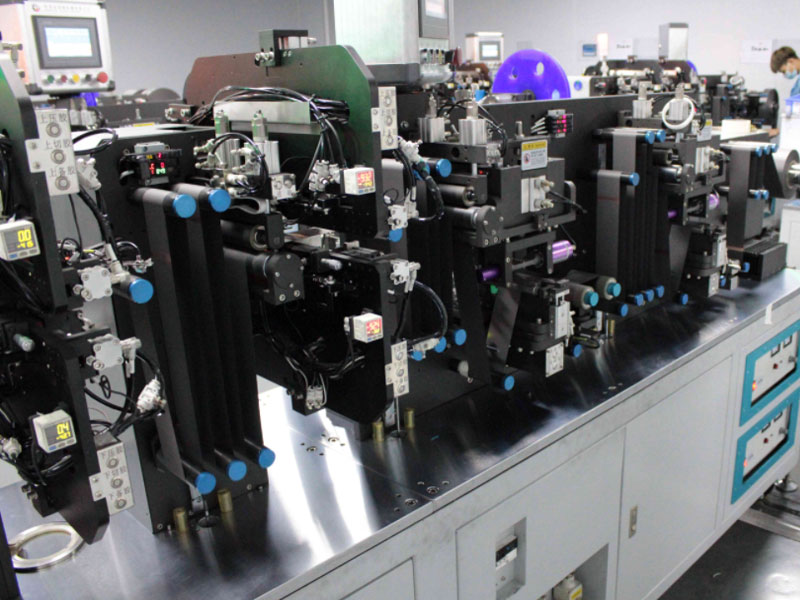

3.Pressing

Rolling refers to the process of compacting the coated product to the specified thickness through two steel rollers under a certain gap and pressure. The influencing factors of rolling include feed angle, gap value, pressure value, rolling speed, winding tension, pole plate temperature, etc. The purpose of rolling is to further compact the loose and porous electrode, reduce the contact resistance between substances, improve the battery capacity within a certain battery volume, and do not overpressure to ensure the infiltration effect of electrolyte on the electrode.

4.Slitting

Slitting is also called slitting. The width of the coated pole piece is large, and the pole piece should be divided into multiple pieces. Slitting products are mainly affected by cutter quality, cutter angle and tension.

5.Tab forming

The process of cutting the pole piece by controlling the engagement between the upper and lower cutter dies of the equipment to form the pole lug according to the design size requirements.

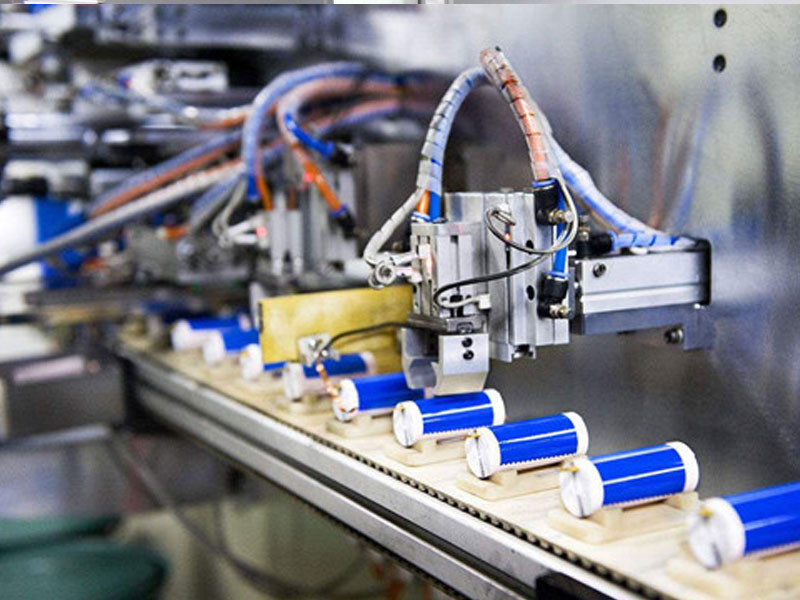

6.Winding

Winding is a form of cell, which is suitable for cylindrical battery, square battery and soft pack battery. By controlling the speed, tension, size, deviation and other factors of the equipment, the negative pole piece, positive pole piece and diaphragm with matching size after slitting are rolled into a bare cell. The key point of winding is that the diaphragm wraps the positive and negative electrodes, and the negative electrode sheet wraps the positive electrode sheet. This requires that the negative electrode cannot expose the foil, which will cause local lithium evolution of the electrode to pierce the diaphragm and cause short circuit.

7.Vacuum baking

Vacuum baking is divided into pole baking and cell baking, both to control the moisture of the cell. Water can be fatal for lithium batteries. After water contacts with electrolyte, hydrofluoric acid will cause great damage to the battery, and the generated gas will also cause battery bulging, etc. The baking efficiency is affected by vacuum degree, drying temperature and time. By adjusting the baking process, try to dry efficiently under the condition of low energy consumption.

8.Tab welding

Whether it is winding or lamination, the pole lug and fluid collector need to be welded. The positive and negative lugs shall be welded at the fluid collecting position to ensure the welding strength and prevent the lugs from falling off. Ultrasonic welding is generally used as the polar lug welding method. Its principle is that under the condition of auxiliary pressure, the high-frequency vibration wave is transmitted to two objects to be welded through the welding head and welding seat. The two contact surfaces to be welded rub against each other and molecules diffuse each other to form molecular fusion welding together. Ultrasonic welding strength is affected by welding pressure, amplitude, frequency, time, welding machine stability, welding head quality, tooling, material hardness, etc.

9.Packaging

The packaging forms mainly include metal shell packaging and aluminum-plastic film packaging. The metal shell includes steel shell and aluminum shell, which is suitable for cylindrical battery and square battery, and the aluminum-plastic film packaging is suitable for soft pack battery. For 18650 cylindrical battery, the packaging step is to put the winding core into the steel shell after winding, then conduct spot bottom welding, rolling groove and liquid injection, then conduct laser welding cap, and finally mechanical sealing. For the square battery, the packaging step is to conduct laser welding and sealing after entering the shell, and then complete the final sealing after liquid injection into the liquid injection hole. The difference of soft pack battery packaging is that it is encapsulated with aluminum-plastic film. The aluminum-plastic film is composed of three layers, PP layer, aluminum layer and nylon layer. The key of packaging is to bond the PP layers together after melting. The heat sealing is mainly affected by temperature, heat sealing time and heat sealing pressure. It is necessary to ensure that there is no poor heat sealing, no sealing, etc. Special attention shall be paid to the top seal at the pole ear, which shall not only ensure that the PP layer of aluminum-plastic film and the PP layer on the outer surface of the pole ear are well bonded and sealed, but also ensure that the PP layer of aluminum-plastic film in the non pole ear area is well bonded and sealed face to face. In addition, compared with metal shell batteries, aluminum-plastic film soft pack batteries need to be coated with a protective film after heat sealing to prevent scratches on the aluminum-plastic film by external substances.

10.Leak test

The process of detecting whether the battery has leakage by negative pressure detection method or helium detection method. Air tightness test is very necessary. Poorly sealed batteries will introduce moisture and impurities, resulting in side reactions with electrolyte in the battery and battery scrapping.

11.Electrolyte injection

Electrolyte is a channel for lithium ions to move inside the battery, which is mainly composed of solutes and solvents. The solute is lithium hexafluorophosphate. Generally, three or more solvents are used together, such as EC / DMC / Dec. The liquid injection process is to inject the electrolyte into the cell. The control parameters mainly include the amount of electrolyte, injection pressure, time and so on.

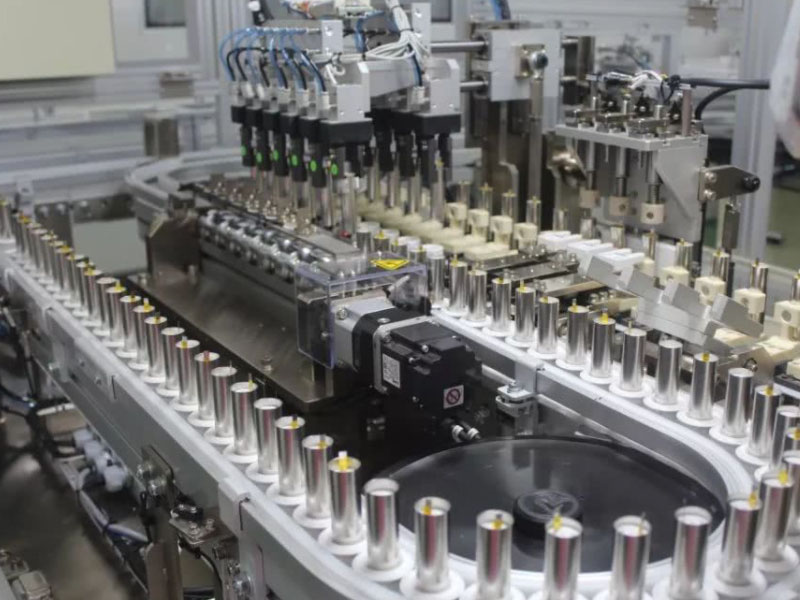

12.Formation

Formation is the first charge and discharge of the battery after liquid filling and sealing. There are two main purposes of formation: first, after the battery is manufactured, the electrode material is not in the best applicable state, or the physical properties are inappropriate (such as too large particles, not close contact, etc.), or the phase itself is wrong (such as metal oxide negative electrode of some alloy mechanism), so it needs to be activated by the first charge and discharge. Second, when the lithium battery is charged and discharged for the first time, electrons reach the graphite negative electrode surface through the external path and react with electrolyte solvent and lithium ion to form a solid electrolyte membrane (SEI). SEI has an important impact on the performance of lithium battery. The formation process has a great impact on the performance of the battery, because factors such as charging and discharging current and time have a great impact on key parameters such as high-quality SEI formation, gas production and resistance.

13.Aging

Aging generally refers to the placement after the first charging and formation after the completion of battery assembly and liquid injection. It can have normal temperature aging or high temperature aging. Both functions are to make the properties and composition of SEI film formed after the initial charging and formation more stable and ensure the stability of battery electrochemical performance.

After aging, the battery shall be finally divided into parts, and it can be delivered after passing the resistance, voltage drop and other tests.

Want to produce customized lithium battery according to special requirement, welcome to consult ELB team to get more details.

THE ELB BRAND PROMISE

QUALITY

4000 TIMES CYCLES 10 YEARS DESIGN LIFESPAN

CERTIFICATION

ISO9001:2015,ISO14001:2015,OHSAS18001:2007 CE, CB, UL, KC, FCC, BIS, IEC62133.

SERVICES

EXW, FOB, DAP, DDP OPTIONAL

T/T, L/C OPTIONAL