Battery Cells

-

18650 2000mAh Low Temperature Lithium Batteries

Read more -

18650 2600mAh Low Temperature Lithium Batteries

Read more -

2000mAh 18650 Rechargeable Battery

Read more -

2600mAh 18650 Rechargeable Battery

Read more -

3250mAh 18650 Rechargeable Battery

Read more -

14430 Battery

Read more -

14500 Battery

Read more -

14650 Battery

Read more -

16340 battery

Read more -

16650 Battery

Read more -

18350 Battery

Read more -

18500 Battery

Read more -

20700 Battery

Read more -

21700 Battery

Read more -

26650 2C and 20C High Rate Battery

Read more -

32650 Battery

Read more

DIDN’T FIND WHAT YOU WERE LOOKING FOR?

FAQ - Battery Cells

Cells is the basic unit of the battery pack, Here we’d like to recommend the multi cell model for different requirement. Such as 14500 battery, 16650 battery, 18650 cell, 20700 cell,21700 cell, 32650 cell, etc.

Also ELB develop the cells with different raw material. Three typical cells are NCM cells , LiFePO4 cells, LTO cells. Which can meet the different requirement in ELB deep cycle battery cell family.

ELB cells are widely applied for the battery of vehicles, power tools, energy storage systems, consumer electronics, etc.

What are battery cells?

A battery cell is a single chemical unit consisting of two electrodes and some chemicals. Fundamentally, a lithium cell consists of four main parts; the negative electrode (anode), the positive electrode (cathode), the electrolyte, and the separator. These chemicals react together, absorbing electrons at one electrode and producing electrons at the other — like an electron pump. A specific set of chemicals “pumps” electrons at a specific pressure, which we call cell voltage.

A given set of chemicals will only produce one voltage. The voltage of the same material is constant regardless of the size of the battery cells. You can add more chemistry to the battery cell, but it just means that the cell can cycle at this voltage for more charges before the chemistry runs out. We usually measure this charge in mAh or Ah. Therefore, a battery cell is an electrical energy storage product that utilizes ions to store electrical energy.

For example, the nominal voltage of lithium ion cells is about 3.7V, lithium iron phosphate cells are 3.2V, alkaline cells are 1.5V, and nickel-metal hydride cells are 1.2V. However, in each case you can buy batteries of different sizes, ie: different mAh capacities.

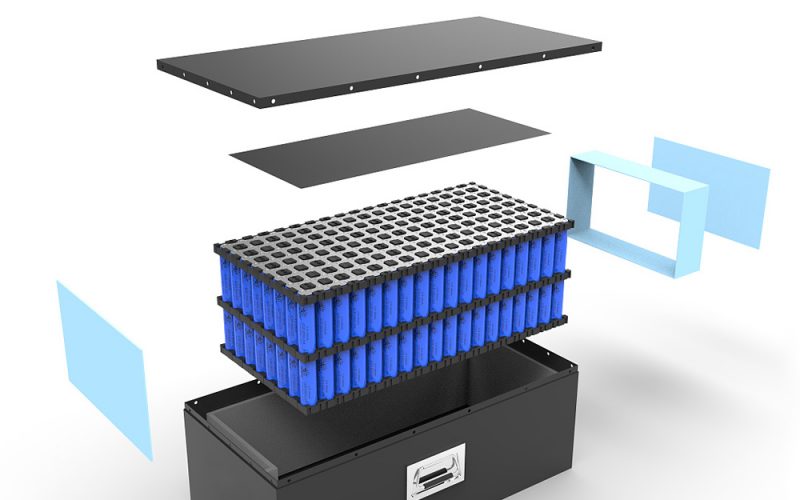

The only way to generate higher voltages without electronics is to connect multiple cells in series, i.e. assemble multiple cells into a battery pack. The entire energy storage unit is called a battery or battery pack. The smallest part that can hold energy by itself is called a battery. Solder the desired number of cells together to form the battery pack. An EV battery pack can hold thousands of lithium-ion cells and weigh about 650-1,800 pounds (about 300-800 kilograms). According to different combinations, lithium batteries can be made into different types and shapes.

How does lithium battery cells work?

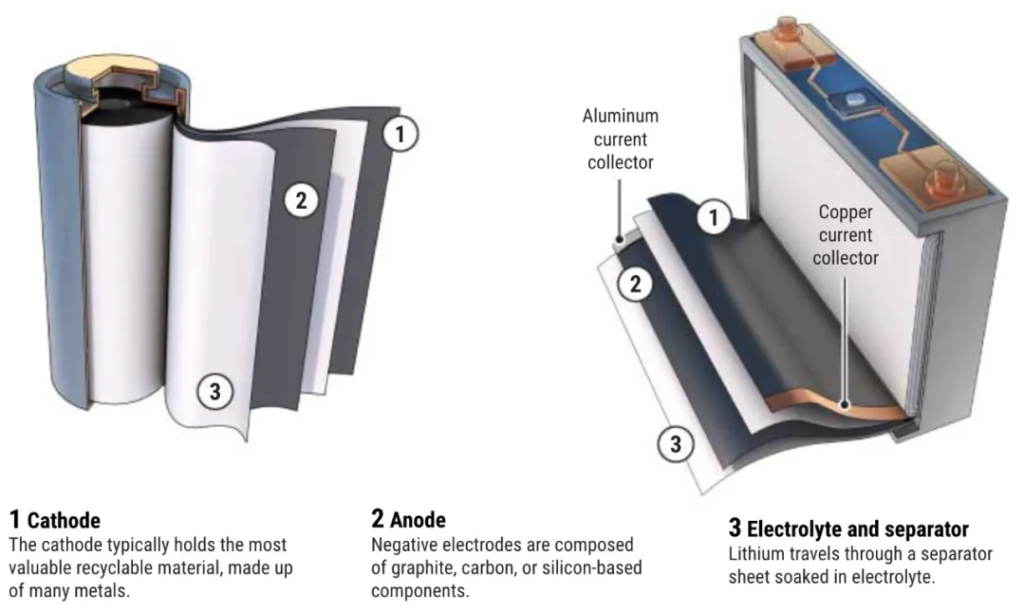

Structure Of Lithium Cells

Just as below picture, the structure of battery cells are main made up of Cathode, Anode, And electrolyte and separator.

Working Principle Of Lithium battery Cells

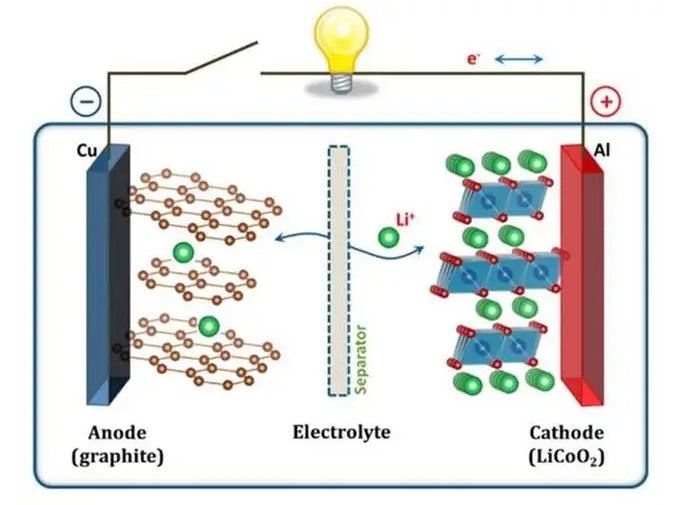

Lithium cell uses a anode (negative electrode) , an cathode (positive electrode)and electrolyte as conductor.

The anode of a discharging battery is negative and the cathode positive.

A separator creates a barrier between the cathode and anode, preventing the electrodes from touching while allowing electrical charge to flow freely between them.

The cathode is metal oxide, and the anode consists of porous carbon. During discharge, the ions flow from the anode to the cathode through the electrolyte and separator. Charge reverses the direction and the ions flow from the cathode to the anode.

Below picture illustrates the process.

What shape of battery cell does ELB make?

Cylindrical lithium cell

Lithium cylindrical cells consist of sheet battery anodes, cathodes, and separators that are sandwiched, rolled up, and packed into cylindrical cans. This type of battery was one of the first to be mass-produced and is still very popular. The battery has multiple rows with arresters on opposite sides. They are bonded to the busbars by soldering techniques and are optionally wirebonded. In this case, no support plate is required. Cylindrical cells must be secured into the battery module or battery pack by rigid spacers, spacer strips, or mounting brackets. In addition, glue can be used as the primary fixation for cylindrical cells. These fixtures add weight and complexity to the battery pack.

Pouch lithium cell

Lithium pouch cells do not have a rigid outer can and use a sealed flexible foil as the battery container. The electrode layers and separator layers of the pouch battery are stacked. For pouch cells, designers should allocate enough space for possible expansion. Modules with pouch batteries show a single row of batteries with arresters on the same or opposite side. The pouch cells can be connected by adhesive bonding welding and can be connected in tab-to-tab or tab-to-busbar bridges without support. Furthermore, they can be connected by a form-fit connection using screws and bus bars as bridges without any support plate.

For pouch cells, the cell frame is usually used as the primary fixation. In this case, the battery is inserted, redundantly sealed and flexibly tensioned. The space between the batteries can even be used additionally for the cooling system. Optionally, pouch cells can even be glued.

Prismctic lithium cell

Lithium prismatic cells consist of large sheets of anode, cathode and separator that are sandwiched, rolled up and pressed into a metal or hard plastic case in the form of a cube. Electrodes can also be assembled by layer stacking. Prismatic lithium batteries have single or two rows of modules, and the arrester is always on the same side no matter which row is in.

Prismatic cells are either bonded to the busbars and support plates by welding, or connected by screws/]pulls/form-fits or as a connection technique and holes – the busbars as bridges. Finally, prismatic cells can be fixed by gluing. This requires a lightweight and resilient connection medium to avoid air pockets.

Prismatic Lithium Cell

What material of battery cell does ELB make?

LFP Battery cell

An LFP battery cells also called lithium iron phosphate battery cells. LFP battery cell is a highly stable but slightly less energy dense battery composition. The iron and phosphate used to make the cathode are abundant and cheap than some of the materials used in NMC batteries – mainly cobalt. In addition, the materials in LFP batteries are far less toxic than those in NMC, making them easier to recycle at the end of their life.

LFP Battery Ccell Summary Table

| Voltages | 3.20, 3.30V nominal; typical operating range 2.5–3.65V/cell |

| Specific energy (capacity) | 90–120Wh/kg |

| Charge (C-rate) | 1C typical, charges to 3.65V; 3h charge time typical |

| Discharge (C-rate) | 1C, 25C on some cells; 40A pulse (2s); 2.50V cut-off (lower that 2V causes damage) |

| Cycle life | 2000 and higher (related to depth of discharge, temperature) |

| Thermal runaway | 270°C (518°F) Very safe battery even if fully charged |

| Cost | ~$200 per kWh |

| Applications | ESS, EVs, etc |

LFP battery cell Summary Table

NMC Battery cell

An NMC battery cell also means NiCoMn battery cell. Which is a very high specific energy or power battery. This limitation of “energy” or “power” makes them more commonly used in power tools or electric cars.

The NMC cells typically have a lower upfront cost but may need to be replaced over the lifetime of the vessel depending on the operational profile. NMC batteries have been the subject of a number of investigations around fires on both land-based and marine installations, leading some companies, such as Tesla, to completely switch over to the use of LFP chemistry for the EVs.

NMC Battery Cell Summary Table

| Voltages | 3.60V, 3.70V nominal; typical operating range 3.0–4.2V/cell, or higher |

| Specific energy (capacity) | 150–220Wh/kg |

| Charge (C-rate) | 0.7–1C, charges to 4.20V, some go to 4.30V; 3h charge typical. Charge current above 1C shortens battery life. |

| Discharge (C-rate) | 1C; 2C possible on some cells; 2.50V cut-off |

| Cycle life | 1000–2000 (related to depth of discharge, temperature) |

| Thermal runaway | 210°C (410°F) typical. High charge promotes thermal runaway |

| Cost | ~$420 per kWh |

| Applications | E-bikes, medical devices, EVs, industrial |

NMC Battery Summary Table

LTO Battery cell

Lithium titanate battery cell battery also refers to LTO battery. Because of its structural stability, it can be used in low temperature, high temperature, and high rate applications. Generally, the number of cycles can reach more than 20,000 times, but the initial cost is 4-5 times higher than that of ordinary lithium batteries. Because of the high price, it has not been popularized on the market.

LTO Battery Cell Summary Table

| Voltages | 2.3V nominal; typical operating range 1.8-2.8V/cell |

| Specific energy (capacity) | ~Wh/kg |

| Charge (C-rate) | 3-10C typical, charges to 2.8V; 15-60 minutes charge time typical |

| Discharge (C-rate) | 3-10C typical, ; 15C pulse (2s); 1.8V cut-off |

| Cycle life | 20000 and higher |

| Thermal runaway | 270°C (518°F) Very safe battery even if fully charged |

| Cost | ~$800 per kWh |

| Applications | Special application, ESS, EVs, etc |

LTO battery cell Summary Table

Why choice LFP lithium battery cells?

Lightweight And Compact

The electrodes (lithium and carbon) commonly used in LiFePO4 batteries are inherently light. Making them smaller and lighter than older batteries such as lead-acid batteries. For comparison, a typical 100Ah (= amp hour) Li-Ion battery weighs about the same as a 40Ah lead-acid battery (about 10-12kg). But has more than twice the capacity.

100% Depth Of Discharge (DOD)

Maximize your energy potential with 100% Depth of Discharge. This means that you can use 100% of the battery’s capacity to power your specific needs. Horever, Lead-acid/ AGM batteries slowly decrease their power and performance while the charge depletes.

High Energy Density

Lithium has the ability to release and store large amounts of energy. Enabling lithium iron phosphate batteries to package high energy capacity in a small size. This means that a lithium battery of the same weight will last much longer between charges than other rechargeable batteries. While still maintaining its high level of performance.

Low Maintenance

Older rechargeable battery types, such as nickel-cadmium or nickel-metal hydride batteries, have what’s called the “memory effect” or “inert cell effect”. If repeatedly partially discharged before charging, the final battery can only supply locally before the voltage drops. Energy used during discharge. To avoid this, NiCd and NiMH batteries need to be fully discharged and recharged on a regular basis for maintenance.

LiFePO4 batteries don’t suffer from memory effect, which means they always use up the last bit of charge. Whether you’re using 100% or 25% capacity, you can charge them without tedious maintenance!

Long Lifespan

High-quality lithium iron phosphate batteries last for about 4000 full charge cycles. A full charge cycle is when the battery is discharged to depletion and then charged to full, so using the battery until it reaches 75% capacity and then plugging it in to charge does not constitute a full charge cycle. When your battery is recharged, you can still use 75% of the charge remaining before charging; only then can your battery complete a full charge cycle.

Low Self-discharge Rate

Lithium batteries also have relatively low self-discharge rates. Self-discharge is a natural, irreversible phenomenon for batteries, where chemical reactions inside the battery reduce the capacity of the battery, even when the battery is not being used. The self-discharge rate of Li-ion batteries peaks at around 3% in the first 24 hours after charging, and then gradually decreases to 1-2% per month. In comparison, nickel-based rechargeable batteries lose about 10-15% of their capacity after charging, and another 10-15% per month.

Difference between LFP battery cells Vs NMC battery cells

Commercially, the initial capital expenditure for LFP cells is generally cheaper than for NMC cells. LFP batteries are about 20-30% cheaper per kWh, but system integration costs tend to be only about 5-15% cheaper at the beginning of the overall system life cycle.

Operationally, we like the LFP’s more relaxed operating conditions – a wider temperature range than NMC, and does not require refrigerated containers for shipping. In addition, LFP battery products generally support up to 1C operation, while NMC must use power batteries, 2H or 4H different batteries use batteries, support 1C rate (1 hour) applications, and the cost is high. For more detail comparison, please read our article LFP Vs NMC Battery: Complete Comparison Guide

Power cells Vs Energy cells: What is the difference?

Power cells usually need to provide the maximum stored energy in the smallest volume, and need to provide the smallest volume under the condition of satisfying electricity. In addition, power batteries usually require the use of high-rate batteries. For example, general car batteries belong to power cell batteries, and they generally require the battery to be fully charged within 1-3 hours to achieve the fast charging function.

Energy storage batteries are generally divided into home energy storage and commercial energy storage. Generally, there is no requirement for volume, and it is not necessary to realize the fast charging function within 1 hour. Therefore, in contrast, power batteries have higher requirements.

CUSTOM BATTERY SOLUTIONS

ELB offer an extensive range of battery sizes and configurations that support various applications. For those applications that require unique power requirements our expert engineers can help design, develop, test and manufacture custom battery solutions for the specific needs of almost any application. Contact us today for more information on our custom battery solutions.

DEDICATED FACTORY SUPPORT

ELB Energy Group is the leading supplier and manufacturers of lithium ion batteries situated in China. This guide is mainly focused on products that the lithium ion battery company is producing and supplying to their target customers. The company is known for providing OEM and ODM lithium batteries to potential clients and customers.

Our blend of domestic and international manufacturing enables us to produce products that feature a range of technologies, price points, and delivery timelines.

LEARN BATTERY KNOWLEDGE

Our battery experts have been committed to spreading new energy knowledge, customizing batteries for various electronic devices, providing battery solutions, developing special batteries, etc.

Check the most professional and real-time battery knowledge, including Battery knowledge, Industry news, Company news, How to, etc

DOWNLOAD TEH ELB PRODUCT BROCHURE AND SPEC

THE ELB BRAND PROMISE

QUALITY

4000 TIMES CYCLES 10 YEARS DESIGN LIFESPAN

CERTIFICATION

ISO9001,ISO14001, OHSAS18001, CE, CB, UL, KC, FCC, BIS, IEC62133.

SERVICES

EXW, FOB, DAP, DDP OPTIONAL

T/T, L/C OPTIONAL