What Is The Function Of The Battery Terminals?

All batteries have positive and negative poles. The positive pole corresponds to a terminal , and the negative pole corresponds to another terminal. The cathode is responsible for taking electrons from the external circuit. On the other hand, the anode is responsible for sending electrons to the cathode. So if you connect the battery terminals, you create a circuit loop in which electrons flow, creating an electrical current.

Most terminals feature a bolt-clamp design. This option provides the strongest possible connection between the wires and the battery. And eliminating the possibility of sparks or overheating due to poor contact.

What Are Battery Terminals Made Of?

There are main two materials that used for battery terminals on the market, lead alloy and tinned copper alloy. Both materials have good corrosion resistance and good electrical conductivity.

Typical Manufacturer of lead alloy. Fastronix Military Battery Terminal.

Typical Manufacturer of tinned copper alloy. Guteauto Store Battery Terminal.

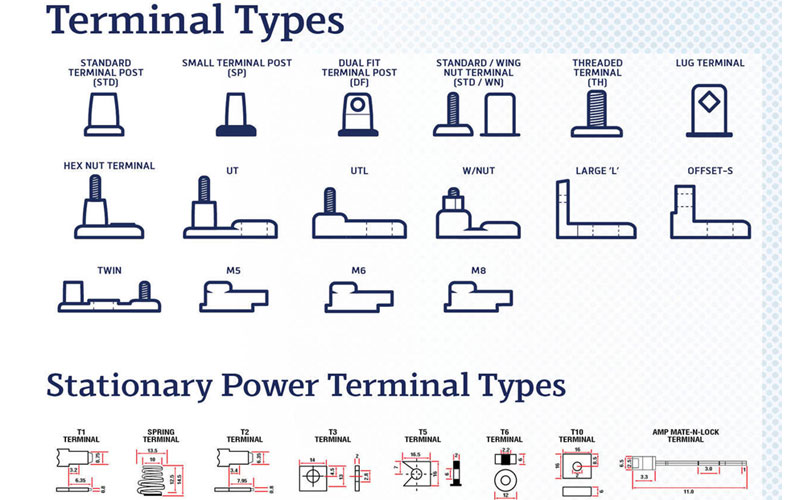

Types Of Battery Terminals

Auto Post Terminal (SAE terminal)

SAE terminal is the most common battery terminal type, and any person who has replaced a car battery can easily recognize it. The positive post is always larger diameter than the negative.

Stud Terminal

Stud Terminal is a 3/8″ threaded SS terminal. Which is designed to fasten and hold the terminal connection to the terminal lug onto the lead base of the terminal.

Dual Post Terminal / Marine Terminal

Dual Post Terminal type has an Automotive Post and a Stud (5/16″). You can make the connection using either a traditional pressure contact or a ring terminal and wing nut connection.

Button Terminal

You will find these button terminals from M5 to M8 which refers to the metric size of the diameter of the bolt thread. For example, if you have a battery with a M6 terminal, you will need a bolt with an 6 millimetre diameter thread. These types of terminals are most commonly found on AGM batteries used in emergency backup and UPS battery applications.

AT Terminal (Dual SAE / Stud type terminals)

AT terminals are commonly found in traction type batteries used in heavy cycling applications such as floor scrubbers and off-grid solar application batteries. This terminal type has an Automotive Post and a Stud (3/8″ threaded stainless steel terminal).

What Is The Influence If The Battery Terminals Are Loose?

Battery terminals Loose will prevent current from flowing properly. The internal resistance increases, which generates heat, and the battery becomes less and less durable. The battery will also be in poor contact, affecting the experience of use.

Why Are Battery Terminals Oxidized?

There are main two reason you need know.

First reason, battery terminals can oxidize due to leakage of battery electrolyte. As the electrolyte vapors leave the battery, they condense on the terminals. This is the reason why the white coating appears. Lead to poor contact, terminal heating and other related failures.

The second reason, when we use the battery in a high humid environment. The terminal metal will also be corroded due to the oxidation of water vapor in the air in the long run.

How To Clean The Battery Terminal?

If you notice any signs of dirt or corrosion on the battery terminals, please follow these steps to clean the terminals.

- Get all necessary cleaning supplies. To ensure effective cleaning of battery terminals, you will need safety glasses, gloves, detergent, battery brush, spray bottle and battery terminal protector.

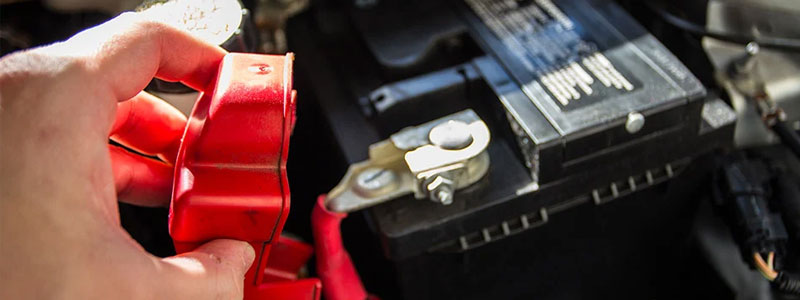

- Continue to locate the battery and disconnect the terminals. Before disconnect the cathode, please connect the anode terminal firstly. Also, make sure the terminals have no metal contact to avoid arcing.

- Now clean the terminals with detergent. Use the battery brush to scrub the terminals as you squirt the cleaner from the bottle. Alternatively, you can use baking soda dissolved in water to clean the terminals.

- Rinse the cleaning agent off the battery with water in a spray bottle and dry.

- After drying, rub/spray the battery protector on the terminals to prevent further corrosion.

When Should You Replace Battery Terminals?

The battery terminals usually last around 50,000 to 100,000 miles. But if the battery terminal are severely corroded and hot, it is time to replace the terminals.

How To Replace The Battery Terminal?

In this video, it shows show you an easy and affordable way to upgrade your dirty or failing battery terminals.