Compared to lead-acid batteries. The lithium batteries is lighter in weight. More efficient in charging and discharging. And has a longer lifespan. But the conditions of use are stricter. Therefore, nearly all lithium batteries on the market need to design a lithium battery management system. to ensure proper charging and discharging for long-term, reliable operation.

A well-designed BMS, designed to be integrated into the battery pack design, enables monitoring of the entire battery pack. And greatly extend battery life. Optimize the charging and discharging performance of the battery. Enhance the safety performance of the battery. Improve battery efficiency, etc.

What Is Battery Management System (BMS) ?

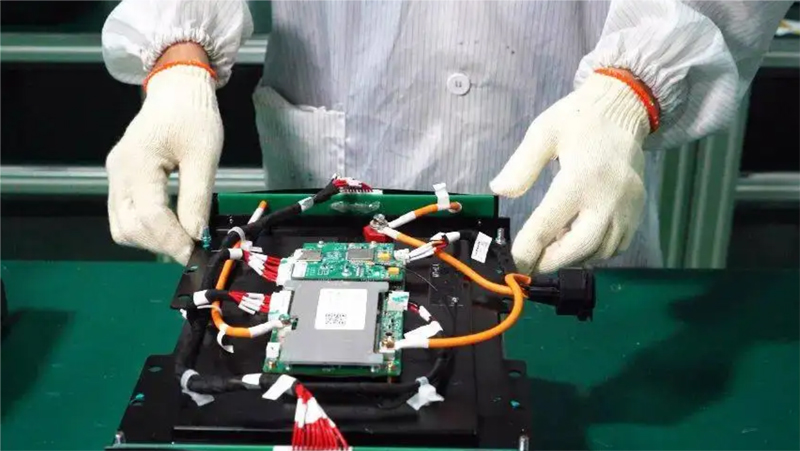

The Battery management system (BMS) is the heart of a battery pack. The BMS consists of PCB board and electronic components. One of the core components is IC. The purpose of the BMS board is mainly to monitor and manage all the performance of the battery. Most importantly, it guarantees that the battery will operate within its stated requirements.

The battery management system is critical to the safe operation, overall performance and longevity of the battery. More over. It protects any lithium battery installed in (boats, RVs, etc.) and the people who use it.

Video Explainaton About The Battery Management System

What Is Function Of The Battery Management System?

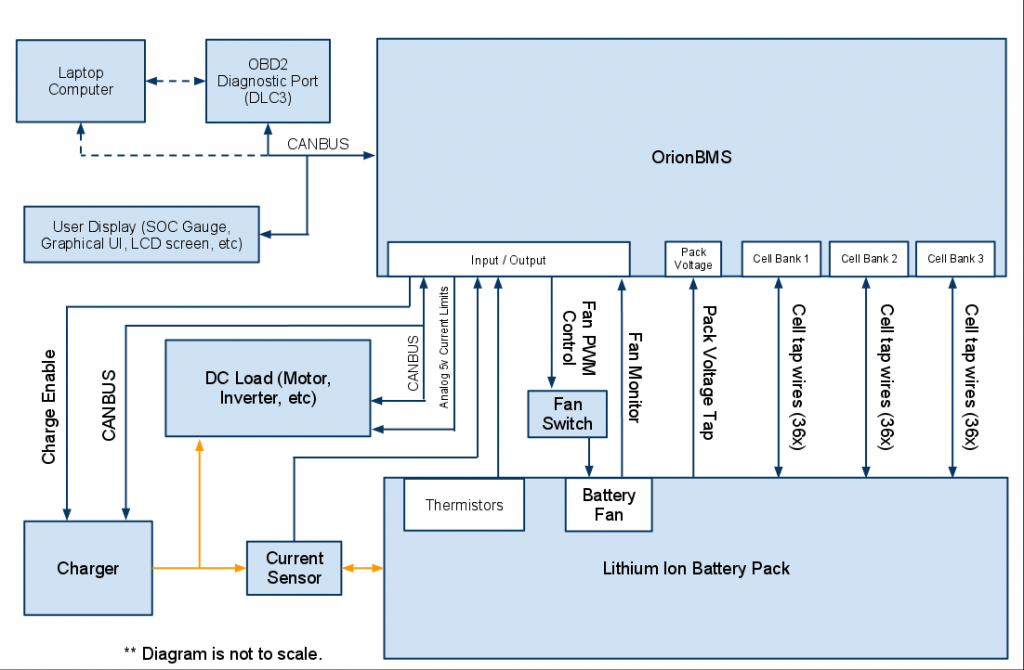

- It prevents the battery pack from being overcharged (too high battery voltage) or overdischarged (too low battery voltage). Thereby extending the service life of the battery pack. At the same time, it works by continuously monitoring each cell in the pack and calculating exactly how much current can safely enter (source, charge) and flow out (load, discharge) without damaging the pack. The BMS board then records and sends these calculated current limits to the sources (usually battery chargers) and loads (motor controllers, power inverters, etc.) responsible for adhering to these limits.

- It calculates the state of charge (energy remaining in the battery) by tracking the amount of power going in and out of the battery pack and monitoring the battery voltage and current. This value can be thought of as a charge percentage indicating how much battery power is left in the battery pack.

- It monitors the health and safety of the battery pack by constantly checking for wiring, loose connections, faulty wire insulation, and the need to replace defective batteries.

How Does The Battery Management System Work?

A job description for a BMS is certainly challenging, and its overall complexity and scope of oversight may span many disciplines such as electrical, digital, controls, thermal and hydraulics.

The battery management system monitors every cells in the lithium battery pack. It calculates how much current can safely enter (charge) and flow out (discharge).

The BMS can limit the current that prevents the power source (usually a battery charger) and load (such as an inverter) from overusing or overcharging the battery. This protects the battery pack from too high or too low battery voltage, helping to prolong the life of the battery.

The BMS also monitors the remaining capacity in the battery. It continuously tracks the energy going in and out of the battery pack and monitors the battery voltage. It uses this data to know when the battery is depleted and turn it off. That’s why lithium-ion batteries don’t show signs of dying like lead acid, but just shut down.

The Benefits Of Battery Management Systems

- Improve the safety performance of the battery.

- Extend life and increase battery reliability.

- Improve charge and discharge performance.

- Diagnose battery status and collect battery data.

- Reduce costs and warranties.

Why Lithium Battery Need The BMS?

Based on so many benefits as above, it is also necessary to use BMS.

Who Make Battery BMS? Recommend 3 Manufacturer.

Systems engineers at Stafl Systems work on a variety of different powertrains and vehicles to maximize performance and reliability. Headquartered in our San Francisco facility. They help customers with vehicle and stationary system integration. Embedded software development, and advanced battery management systems.

A company that can provide a full range of components and PCB boards

ELB is a professional lithium battery manufacturer. but ELB have they own BMS design engineer. Coverable battery BMS from 3.2V to 72V for the entire BMS solution.

Related article: 《Benefits Of Lithium Batteries》

Related article: 《How Do Lithium Ion Batteries Work?》

Are There Still Something That You Want To Know?

I really hope you enjoyed my complete guide to Battery Management system.

Now I’d like to hear from you:

Did your batteries built-in BMS side ? Or if there are still something that we need talk but did not addressed?

Also, I plan on adding even more helpful resources to this article soon.

So let me know if you have any ideas or suggestions.

Either way, let me know by leaving a comment below right now.